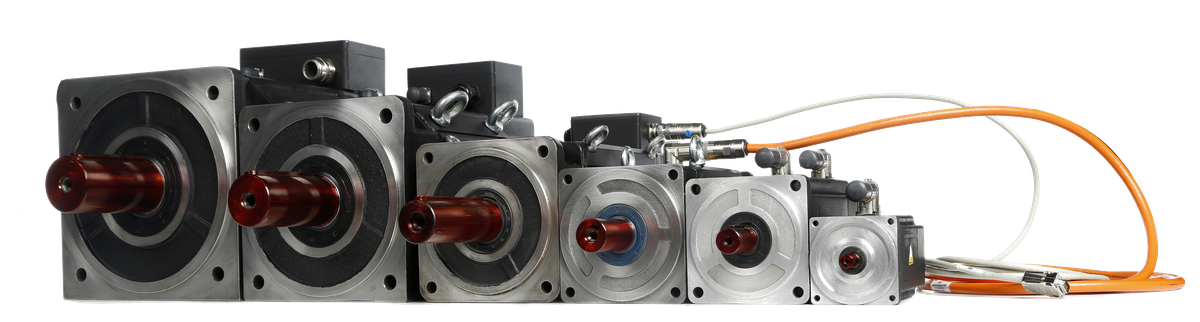

SQM Synchronous Torque Motor

Up to 12,500 Nm torque — gearless direct drive, no water cooling required

SQM is designed for applications that require high torque at low speed with a compact direct-drive solution. It eliminates gearbox-related losses and service needs while delivering stable, controllable motion.